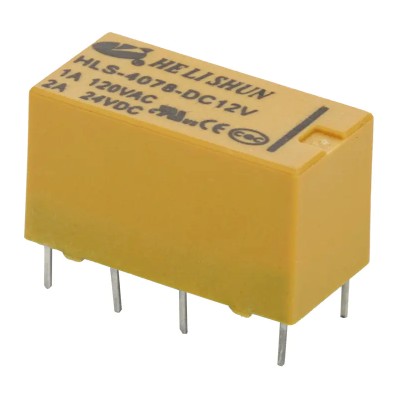

A telecom relay is like an invisible switch: it uses a small control current to operate a separate high-power circuit, providing isolation and allowing remote or automated control. At its core the relay uses electromagnetic principles so a weak electrical signal can control much larger loads safely.

Content

Step 1: Energization and Electromagnetic Induction — telecom relay

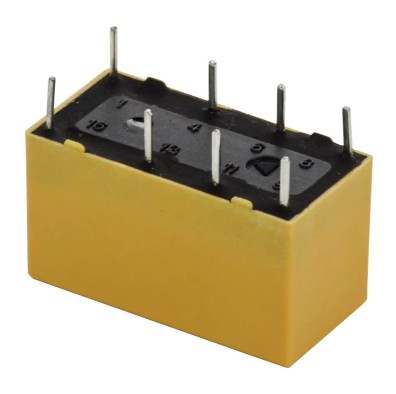

The cycle begins when a control current is applied to the relay coil. Current through the coil generates a magnetic field (electromagnetic induction). The coil and core become temporarily magnetized and produce the attractive force necessary to move the relay's internal moving parts.

Step 2: Attracting the Armature and Closing the Contacts

The magnetic field pulls the armature (a movable iron plate). As the armature moves it carries attached contacts with it. This mechanical action is equivalent to pressing a switch, enabling or disabling the external load circuit depending on the relay type (normally open or normally closed).

Step 3: Opening and Closing a High-Current Circuit

When the armature reaches its operating position the relay contacts change state — they close to complete a circuit or open to break it. This lets the relay control motors, lamps, actuators, or other heavy devices using only the original low-power control signal.

Step 4: Power Off and Reset

When the control current stops, the coil's magnetic field collapses. A return spring (or gravity in some designs) pulls the armature back to its rest position and restores the contacts to their default state. This reset readies the relay for the next control pulse and ensures predictable behavior.

Summary: Core Operating Cycle

The basic cycle is: energize coil → create magnetic field → attract armature → open/close contacts. This sequence gives telecom relays two main advantages: electrical isolation between control and load circuits, and the ability to switch high power remotely or automatically.

Applications and Practical Notes — telecom relay

Relays are used from simple household controls to complex industrial automation, including telecom systems, power distribution, automotive electronics, and control systems. When selecting or using a relay consider these factors:

- Coil voltage — ensure compatibility with your control circuit.

- Contact rating — must handle the load current and voltage safely.

- Switching speed and life expectancy (mechanical/electrical) — important for frequent switching applications.

- Protection features — use a flyback diode for DC coils, and consider arc suppression or snubbers for inductive loads.

- Environmental sealing — sealed or hermetic relays are recommended for harsh environments.

Understanding these steps and considerations helps you choose the right relay and use it safely and reliably in your system.

English

English 中文简体

中文简体